Proprioception on the Cheap¶

Published on 2015-06-04 in Tote.

Remember that time when you sat on your leg for some time, and it got numb, and when you got up, it felt all wooden and walking was like walking on stilts? That’s how most walking robots feel. What happened is your nerves got squished and blocked a little, and you lost your sense of proprioception – the position and forces of your limbs. Now you know why robots that don’t have force and position sensors on them have such a hard time walking!

What if we could add this sense to our robot? It would still be blind and deaf, but at least it would have a sense of self. It could feel its way around, knowing if a leg is standing on the floor or floating in the air, knowing if there is something blocking its movement. If we got smart with programming, we could even make it “obedient” and go in the direction you push it, just like this robot:

OK, well, maybe not as well. After all, we have limited budget and time. Plus programming the algorithm that calculates the overall force from the feedback from all the joint could be a challenge…

But at the minimum we could make our robot stop when it arrives at the edge of the table and tries to put one of its legs in the abyss beyond it. Or when we pick it up.

So how do we do it? We could attach additional sensors to the legs – encoders for the position and pressure sensors for touch and force. I checked the parts – they are either expensive or problematic to mount on such a robot. But wait, doesn’t the hobby servo already know its position? Why not use that?

The first approach was to use an additional wire added to the servo’s potentiometer to read its position. I used this excellent guide on modifying the servo . It worked. Kinda. But not as well as I hoped. The problem is that to deduce what force is applied on the leg, I need to calculate the difference between the desired position of the servo and the actual position. This difference is going to be small, because the servo’s electronics are working hard to correct it. Turns out that they are smaller than the noise, even if I add filtering capacitors and software filters. Oh well.

Then I realized that the servo’s electronics is actually already calculating the force, for its own purposes. Can I somehow plug into that? What if instead of reading the pot’s position, I would simply read the voltage that the servo is applying to its motor? Turns out that this works quite well, at least with the SG90 servos that I have. Here’s an experiment that I performed to test a “compliant motion” servo:

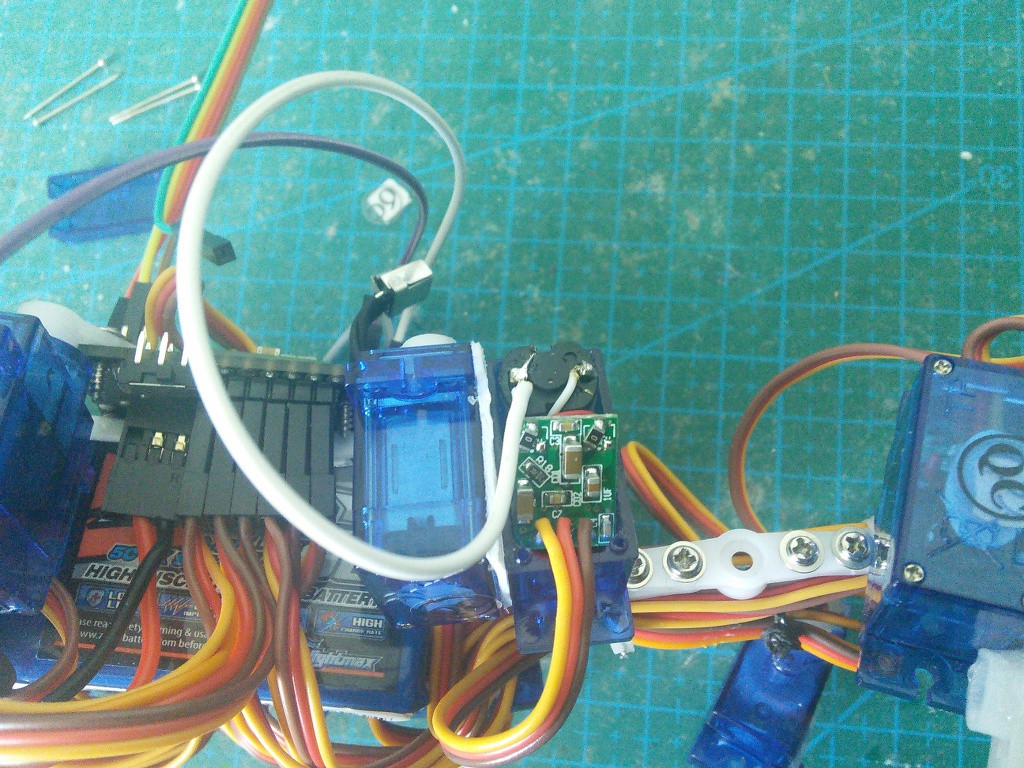

I soldered an additional wire to the servo’s motor, like this:\

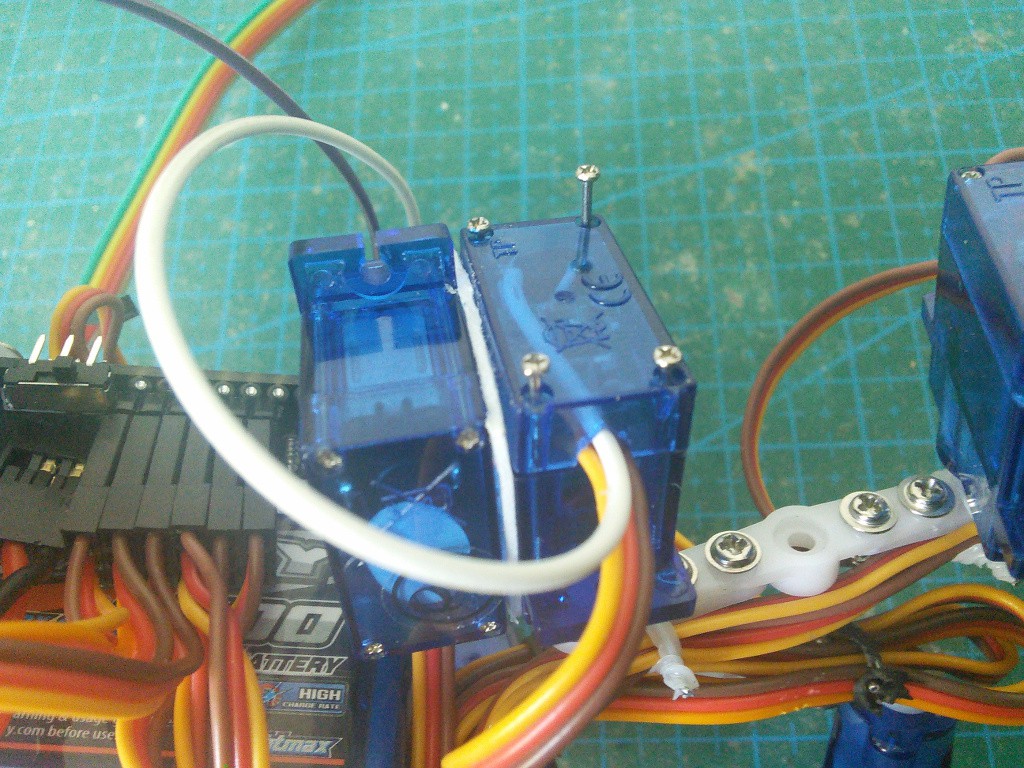

I also had to make the hole in the cover a little bit larger, to fit the extra wire:

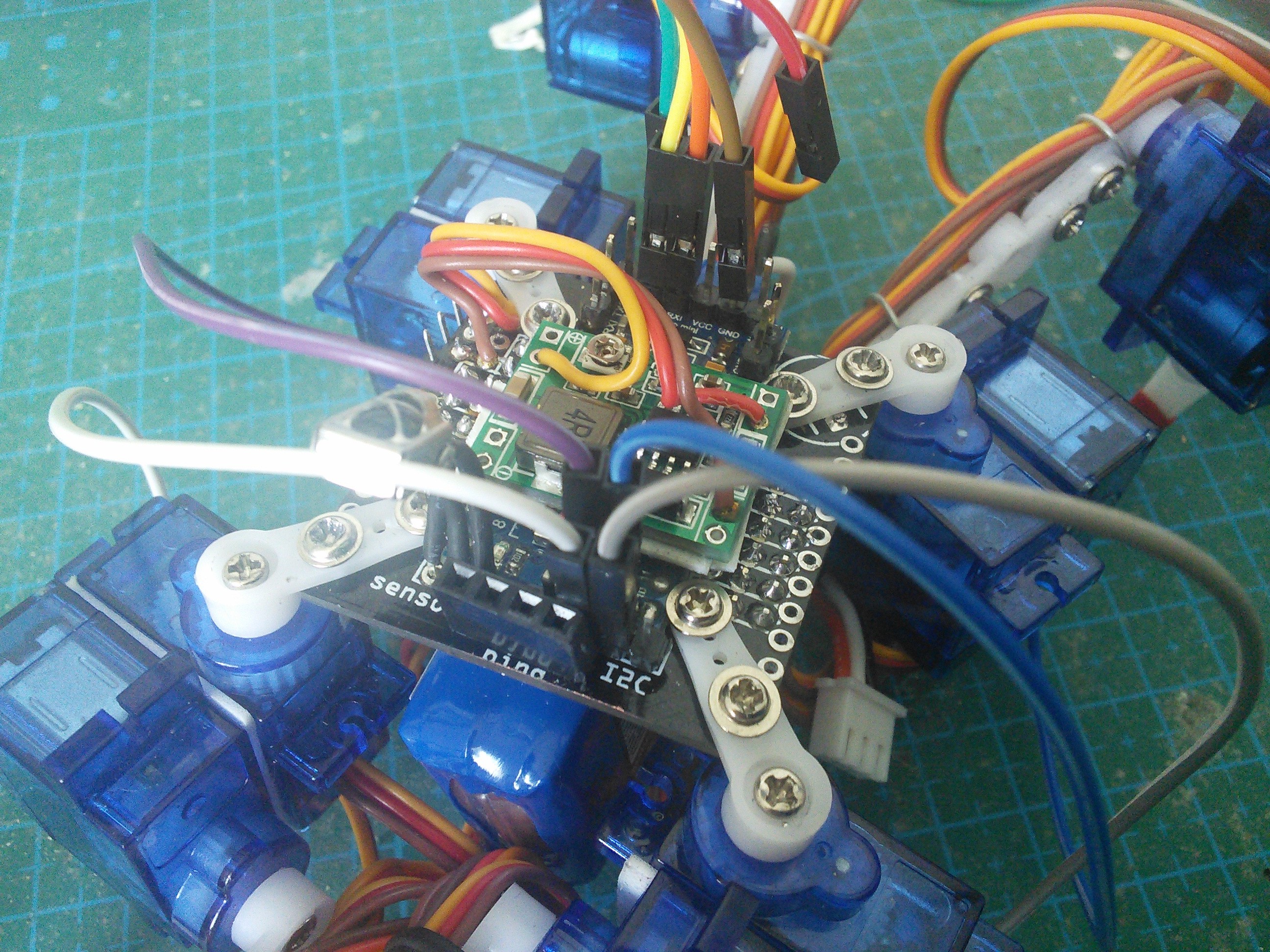

Now, just connect the extra wire to one of the free analog pins on the Pro Mini:

As you can see, the robot also uses a voltage regulator that I described in the previous log . That’s because I need the voltage readings from the motors to be consistent, and not depend on how much juice is left in the battery.Now just a simple addition to the walking algorithm. Every time you put your leg down, wait for the servo to get there, and then read the force from it. If the force is too small, stop. I also made all the other legs move up slightly just before the reading, to shift the weight more to the leg that we are interested in. The result is not very pretty yet, but I’m sure I can tweak it to look better:

With some tricks, I might even be able to make it walk on uneven terrain without additional endstop switches at the ends of the legs.

Update 2015-06-10:¶

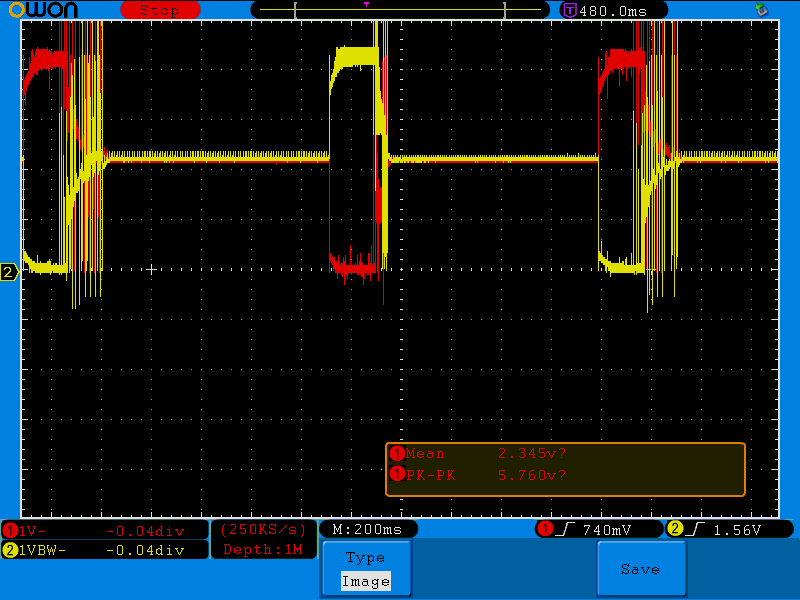

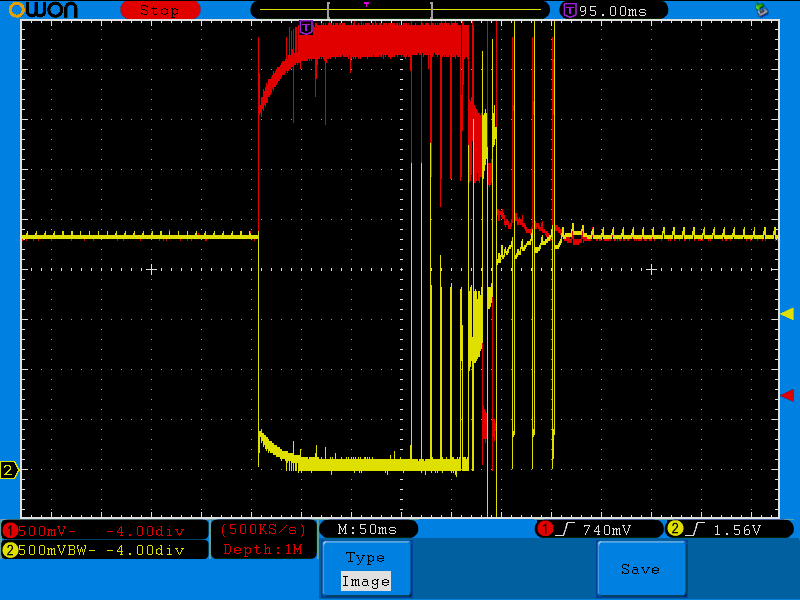

A friend of mine ran some of those servos through an oscilloscope, to see how the voltage on both of the motor wires looks like. Here’s the servo going one way, stopping for a moment, and then going the other way:

You can see that when stopped, the motor floats at about 2.3V, and goes up to 5.7V or almost to 0V when moving. You can also see that there is quite a lot of oscillating at the end, when it overshoots and corrects:

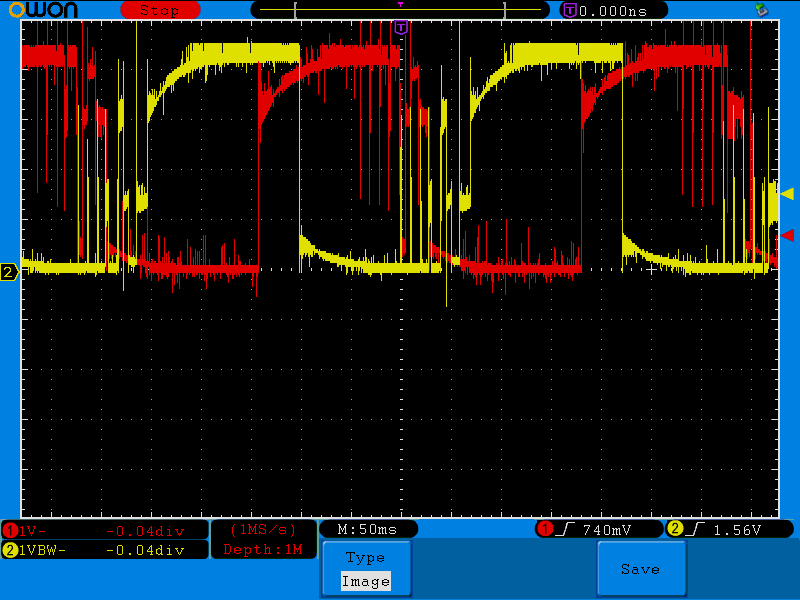

An interesting thing happens when you reverse the direction without stopping:

One of the motor leads gets high voltage long before the other gets low. Since what drives the motor is the difference, this gives the motor some time to stop and reverse, before applying the full force.

deshipu.art

deshipu.art