The Devil in the Details¶

Published on 2023-04-03 in Sly Bug.

While the new servos are mostly a drop-in replacement for the rc servos, there are still some considerations we have to keep in mind. The first potential problem is that I’m powering those servos directly from the LiPO battery, with voltage that is below the recommended minimal voltage of 4.8V. The analog servos didn’t really mind, and a simple trick of increasing their driving frequency helped with any weakness problems they could have. But the new servos have an actual microcontroller inside. Will it work with the lower voltage?

A quick experiment shows that the answer is “yes”. I tried them with voltages as low as 3.2V, and they seem to work perfectly fine. Of course that doesn’t mean there won’t be some problems related to this discovered down the road. I still might need to add a boost converter to the robot to provide a stable voltage.

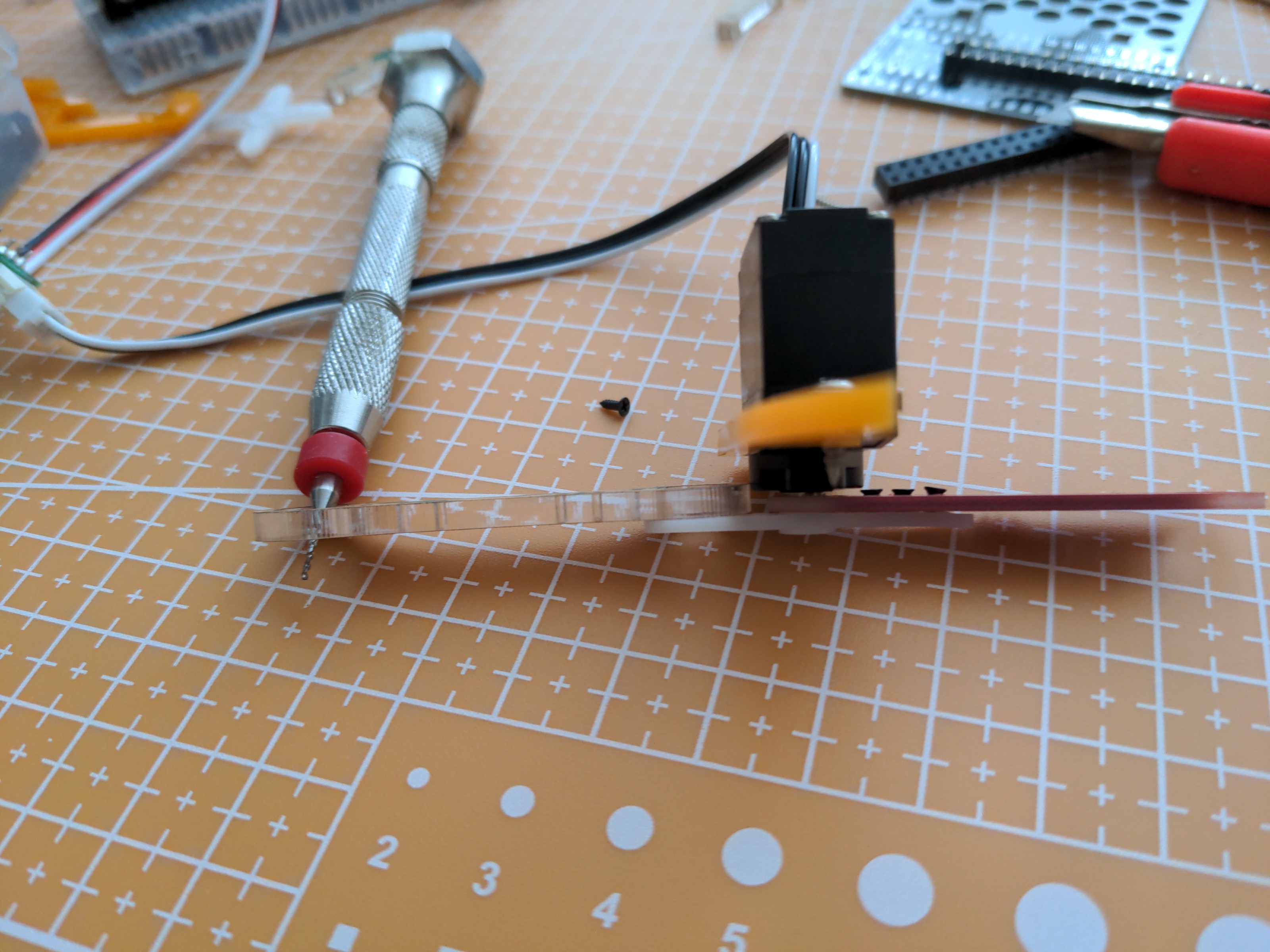

Another problem is mechanical in nature. While the case of those new servos has the same dimensions as those of rc servos, the output shaft is a little bit smaller and shorter. That is not a huge problem, as matching servo horns are provided, but turns out that the difference is enough that the 3mm thick laser-cut leg parts touch the servo case, which is adding unnecessary friction. I might consider cutting new leg parts from 2mm acrylic and with smaller holes for the horns, but for now I will simply use leg parts from earlier versions of the robot, which are made out of 1.6mm PCB that fits well enough.

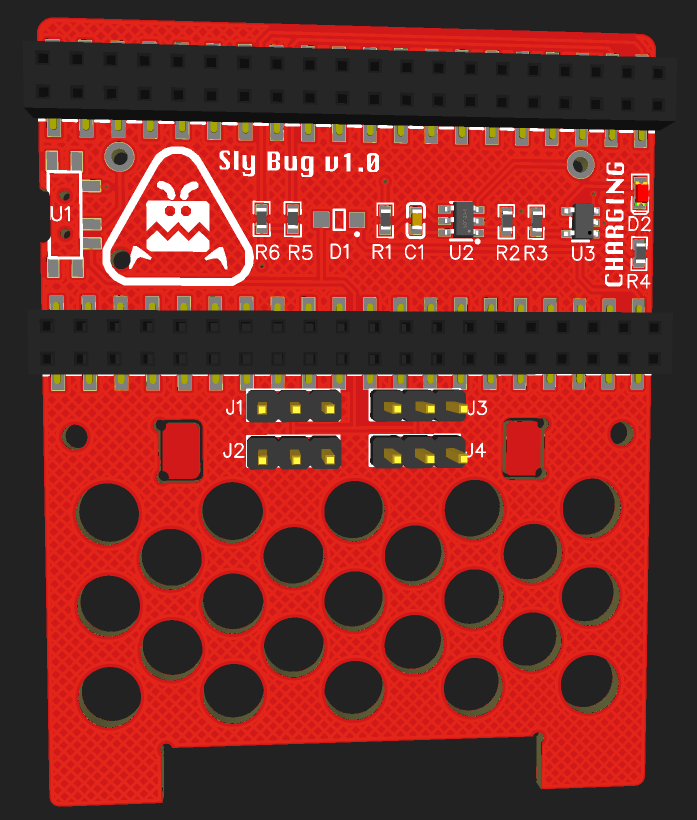

I also designed and ordered a PCB for the body, to connect the servos more conveniently. In the mean time I can just use the extension cables provided with the servos.

deshipu.art

deshipu.art