Preliminary Tests¶

Published on 2018-08-04 in Electronic Barrette Hub.

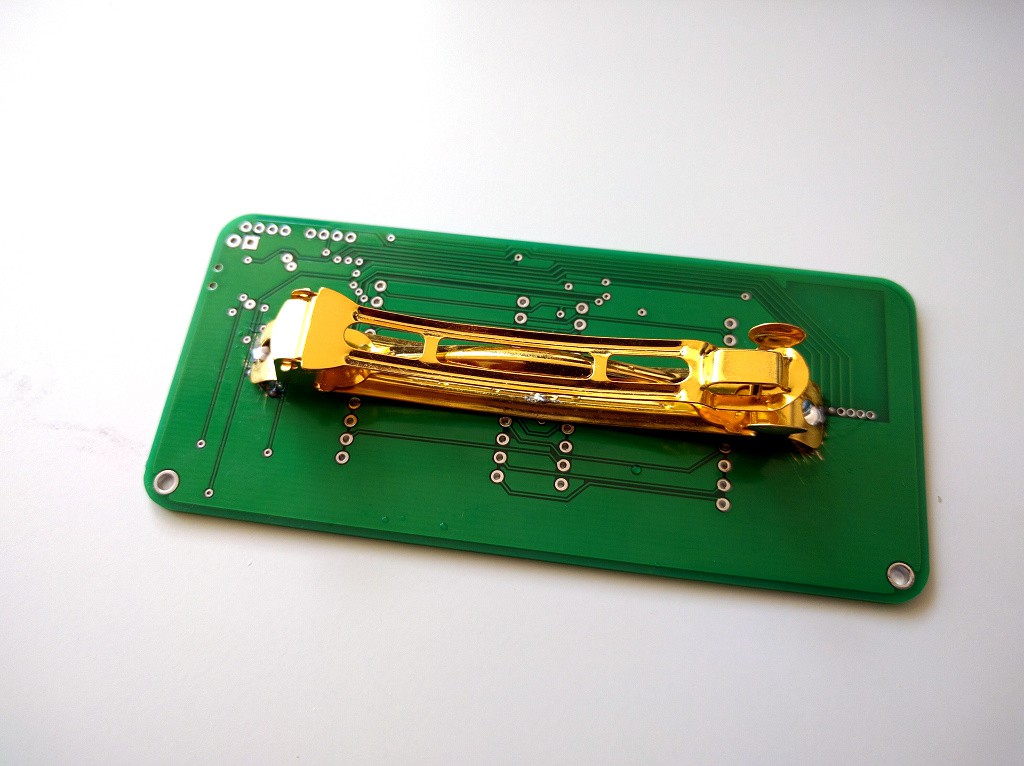

The clasps I ordered a while ago have just arrived, and it’s time to make a practical test of attaching them to a PCB. For that I used one of the old PCBs I have in my box. I scratched the soldermask in three places and tinned it with solder. Then I straightened the clasp a little, bent the ends so that the contact points are all in a straight line, and tinned them.

Next, I put the two together and heated with my soldering iron. The result looks pretty good, and is really strong and solid:

More importantly, the clasp still works, even after being attached to a rigid PCB like this. It’s a little too big for wearing — because the PCB is straight, and not bent, the ends stick out to the sides too much. The actual barrette will need to me a bit shorter.

deshipu.art

deshipu.art